Another plume of new features in GO2cam for workshops for 2020!

For its new version 6.07, GO2cam for Workshops is improving both its toolpaths and additional functionalities, and as always, contains heaps of interfaces. Let’s discover together six key points of this new version!

turnyuGO :Launch of a brand-new high-performance turning cycle

turnyuGO® is the declination of this innovative cycle applied to turning, activable with button tools. It is partly based on a “come and go” toolpath along the part and corner loops. From this way of work results a superfast material removal, smooth transitions and a spotless surface finish.

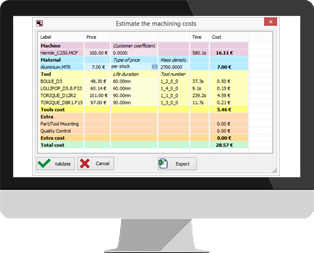

Costs monitoring in GO2cam

What is a production cost? Raw material price, tools, machine use time (and also its depreciation).

We can now assess the production profitability by entering all these costs parameters in GO2cam for Workshops. The software provides precise costs information for each line and calculates the cost price of the current production, a very handy feature for preparing commercial offers!

New toolpath calculation in millyuGO

Already multi-patented, millyuGO® high-performance machining cycle is still progressing on its aim of total efficiency and is improved with a new functionality! In addition of its proved added value in hard materials machining, millyuGO® is now able to machine on a” come and go” path in softer materials such as aluminum, and thus obtains a 30% faster milling time compared to a one-way path.

GO2cam integration in SOLIDWORKS

Few years ago, GO2cam opened a door toward SOLIDWORKS®, launching “GO2cam Feature Exchange”, an add-in which makes easier the data exchange between the two software. By automatic updating of toolpaths and holes features transfer, the process between design and machining already speeded up.

Today, GO2cam goes further and fully integrates into SOLIDWORKS® as an add-in.

The best of CAD and CAM are combined together without transferring files, for a smoother, faster and safer use.

New deburring cycles for a perfect finish!

GO2cam has completed its cycles range with two very fine deburring toolpaths, one available from Mill Classic for 3 axes, the other in Mill Expert for 3 to 5 axes. They are both activable with ball end mill, taper mill cutter and lollipop cutter. The manual work time is thus reduced to the minimal proportion and the surface treatment in all the production is perfectly identical.

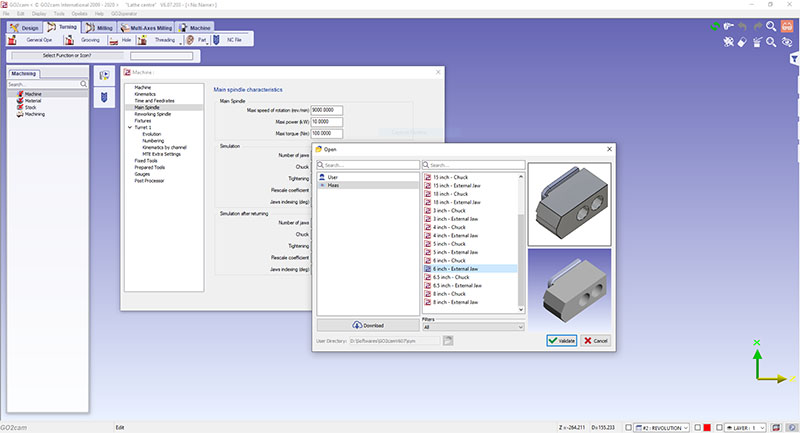

Tools and accessories online library

In order to offer the closest to reality simulation, GO2cam launches an cloud-hosted Library of turning and milling tools, standard tool holders, clamping vices and chucks jaws for turning.

It includes products from Sandvik®, Erowa®, Iscar®, Jergens®, etc. New brands will appear in the coming months without updating needed from the user: that’s the point of a cloud!

For those who didn’t know…

GO2cam is a story about crazy men… crazy about CAM. Founded 10 years ago by a team which worked for large CADCAM software editors, GO2cam is the story of men who put brotherhood and love of well-done work above everything else. A logic that has flourished as GO2cam is today a group of almost 50 people spread over 3 countries. GO2cam for Workshops software suite is running worldwide and the sales network grows every year! Intellectual rigor in ISO files writing, continuous improvement of machinist work, real-time resources optimization are the ingredients of what we called at GO2cam “the art of machining“.