GO2cam for Robots

Optimize Your Robotic Programming with GO2cam’s Integrated Solution

In an ever-evolving industrial landscape, efficiency and precision are crucial. Thus, the integration of Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) technologies has revolutionized our approach to offline programming for robots.

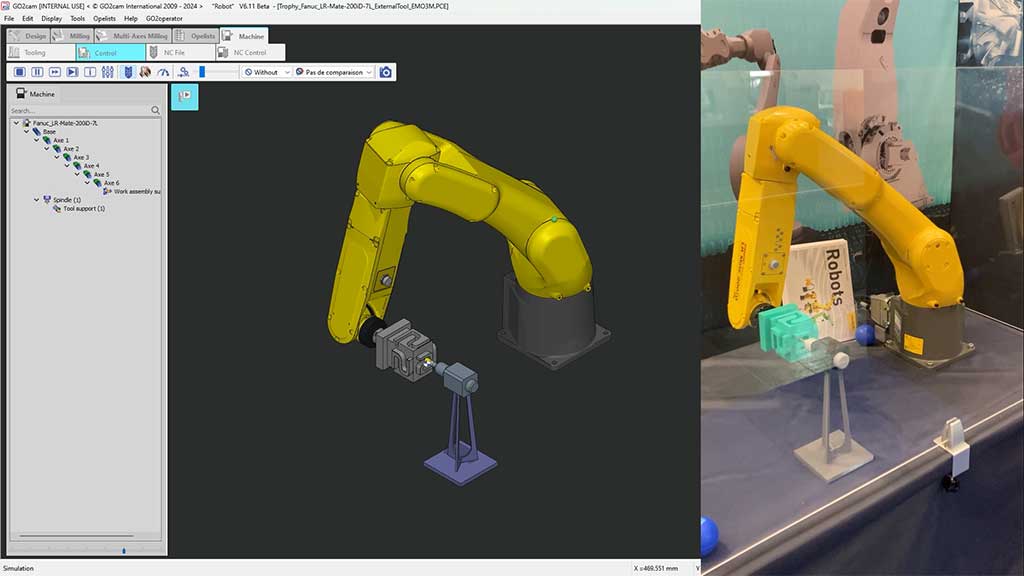

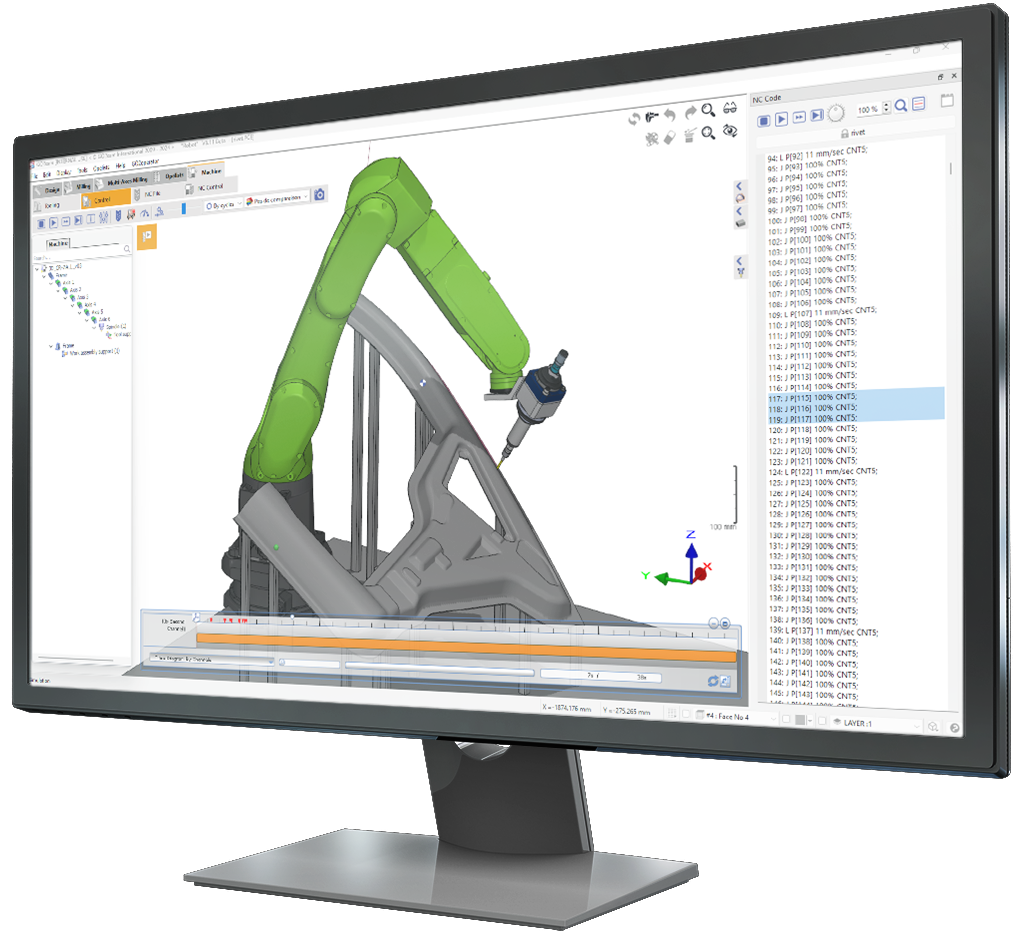

GO2cam offers a comprehensive solution that seamlessly combines the capabilities of CAD/CAM with tools dedicated to offline robot programming. With this cutting-edge system, users can easily create and manage simple or complex tool paths, allowing them to program robots with the same ease as machine tools.

It also allows, by retrieving ‘feedback’ on the robot’s joint positions, to simulate the exact position of the robot as it moves. A response of the robot’s movement is obtained on the screen. It is a real digital twin.

Easy Programming for Various Applications

Whether you are working on basic applications like deburring and cutting or tackling complex tasks such as deposition, gluing, welding, and polishing, GO2cam provides a user-friendly platform.

Consequently, this fully integrated solution allows you to optimize your robot’s performance effortlessly, ensuring a smooth transition from simple programming to managing the most complex applications.

Flexible Robot Setup

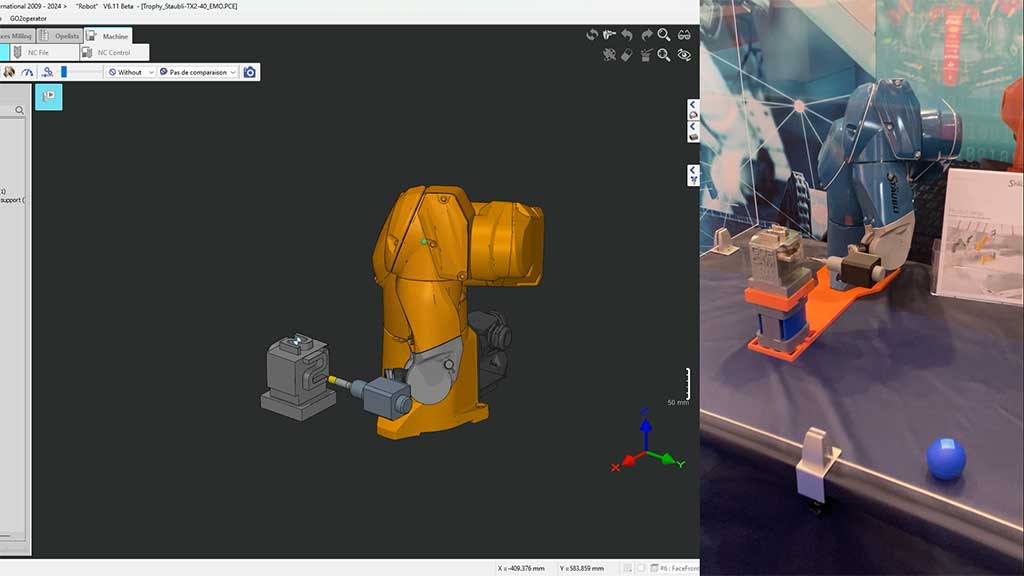

GO2cam‘s robot setup function supports multiple Tool Center Points (TCP) for a single robotic arm.

Thus, users can define the working environment and manage various motion strategies, including multitasking scenarios. The platform enables precise control of the workspace, checks multiple TCP transitions, and intelligently avoids singularities, thereby enhancing overall operational efficiency.

Realistic Simulation for Validation

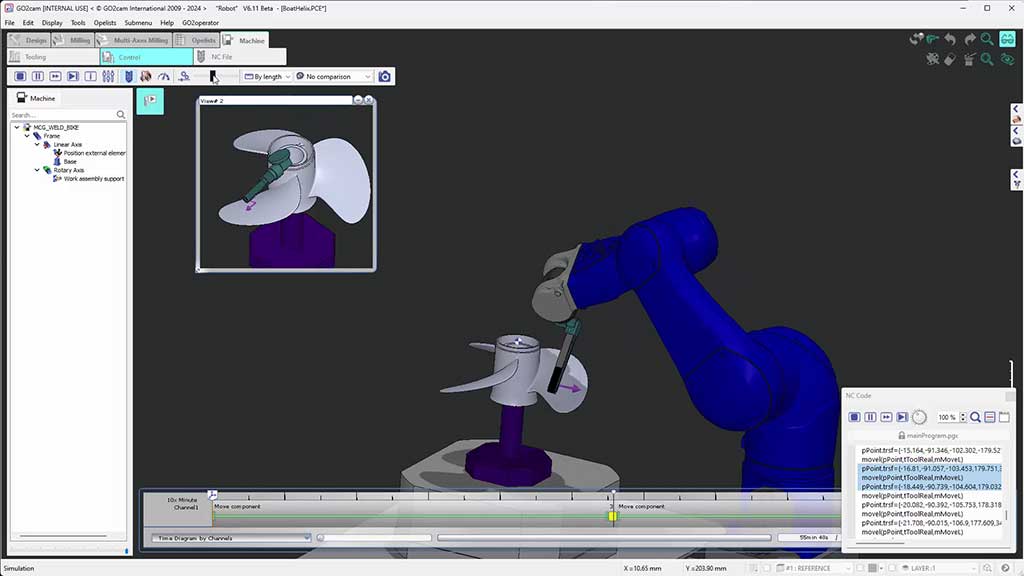

GO2cam offers a powerful simulation feature to validate and optimize robotic programs.

Users can simulate the entire robotic cell, including complementary axes, check and prevent collisions, providing a virtual environment to test and adjust programs.

The dual perspective (POV for Point Of View) – both the main overall view and the specific tool area – offers a holistic approach to program validation

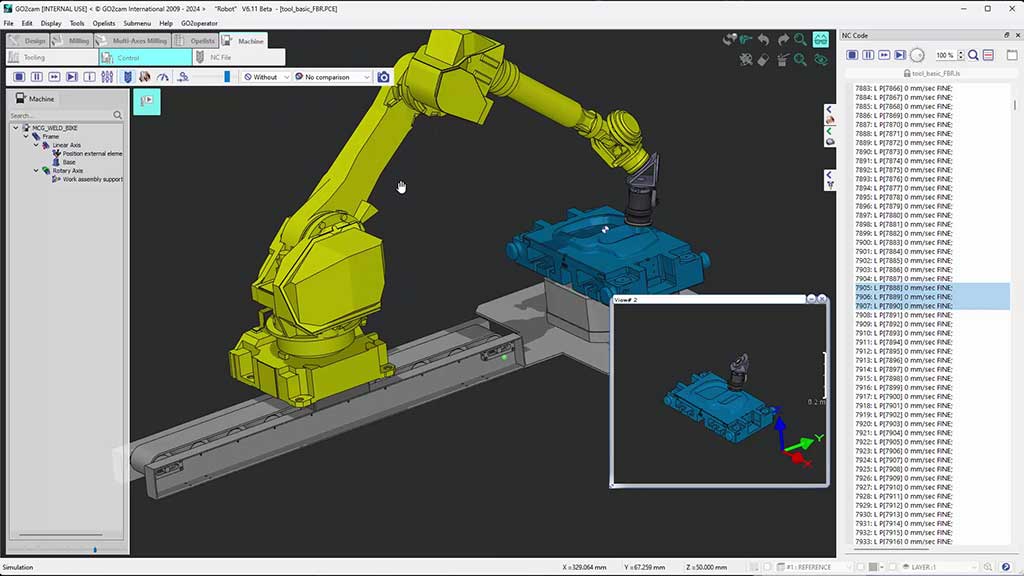

Precise NC File Generation

GO2cam ensures compatibility with leading robot manufacturers such as ABB, COMAU, ELITE, FANUC, KAWASAKI, KUKA, STÄUBLI, STEP, UR, and YASKAWA.

Additionally, the platform provides pre-validated Standard PP libraries, simplifying the programming process. Moreover, GO2cam offers customized solutions in collaboration with manufacturers and integrators, addressing specific needs and ensuring optimal performance for each unique application.

Empower Your Robotic Programming

GO2cam’s integrated CADCAM solution for offline robot programming represents a significant advancement in industrial automation. Thus, with easy programming, flexible robot settings, realistic simulation, and accurate NC file generation, users can enhance their robotic applications across various industries.

Stay ahead in the competitive market by adopting the efficiency and precision offered by GO2cam’s powerful solution. Optimize your robotic programming experience and unlock new possibilities for your manufacturing processes.