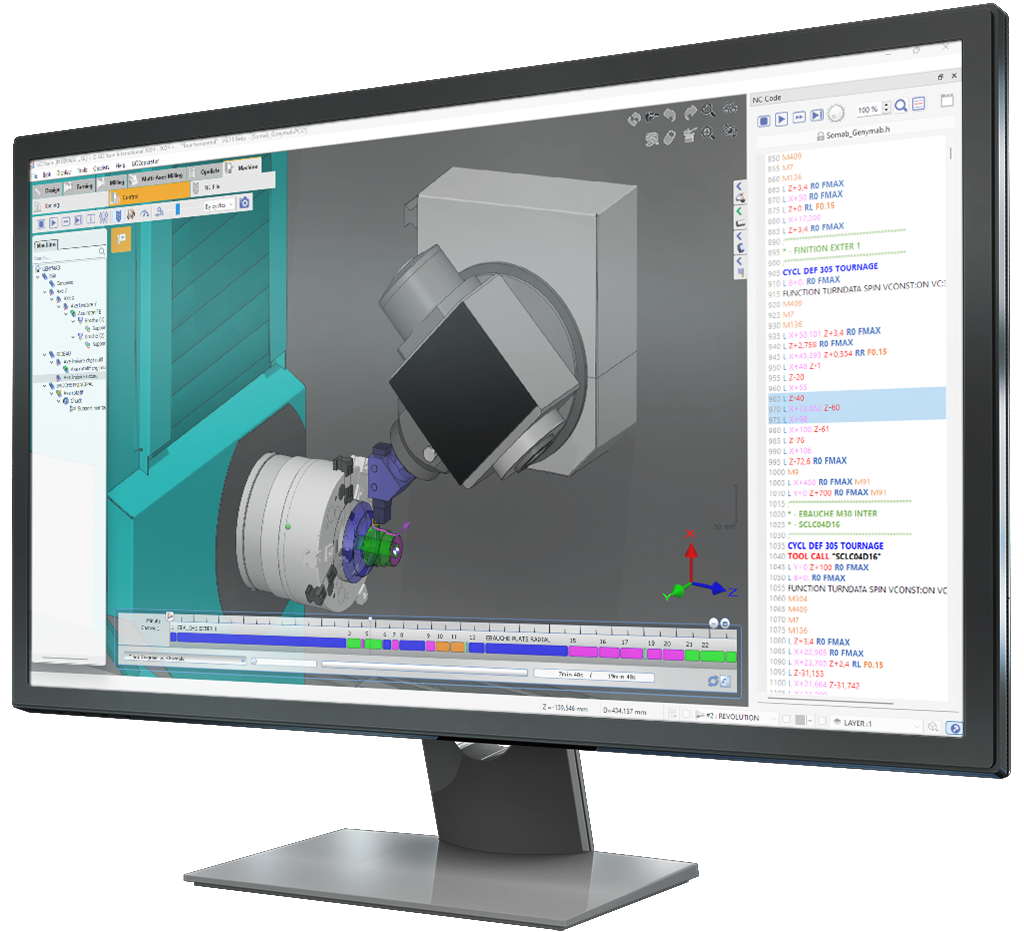

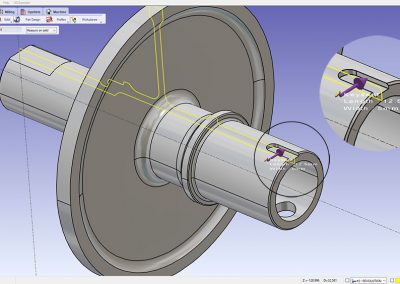

GO2cam TurnMill

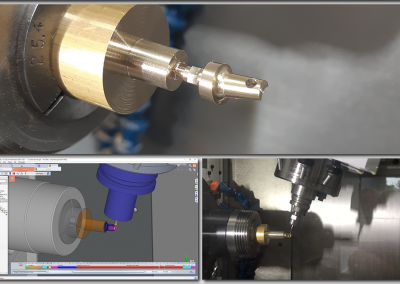

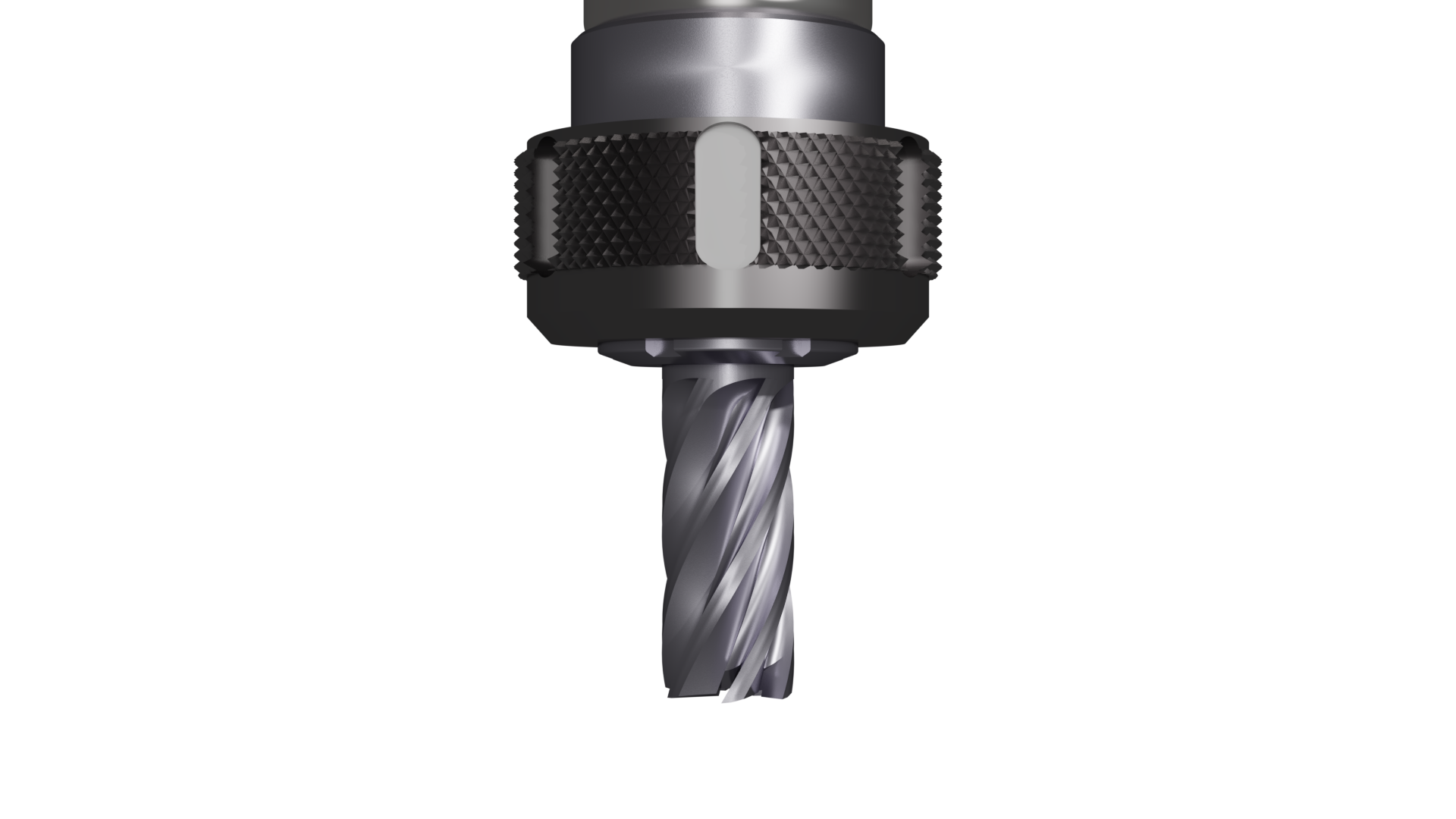

GO2cam develops and markets a software suite which covers all turning operations. Simple turning, B and C axis, 5 axis turning, GO2cam’s range is adapted from simple parts turning to complex machining including threading and Swiss machining.

The advantages of GO2cam TurnMill:

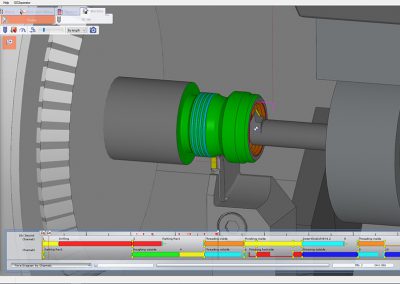

- Amazing automatic input of opelists: Define an OpelistOpeList : knowledge base of machining cycles, technological parameters and cutting conditions suitable for a machine, a material and tools., click and let the software work for you, it will automatically recognize turning features such as facing and grooving! A same range, different parts, the automatic toolpath is created according to the geometry.

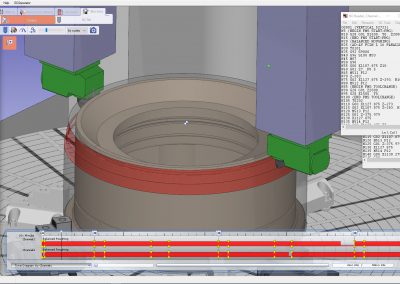

- ISO standard tolerances with maxi, mini and average values.

- Smart topology recognition: chamfers and radius are kept if you modify a length, modification of key seats. Multiple changes are supported (set of identical grooves for example).