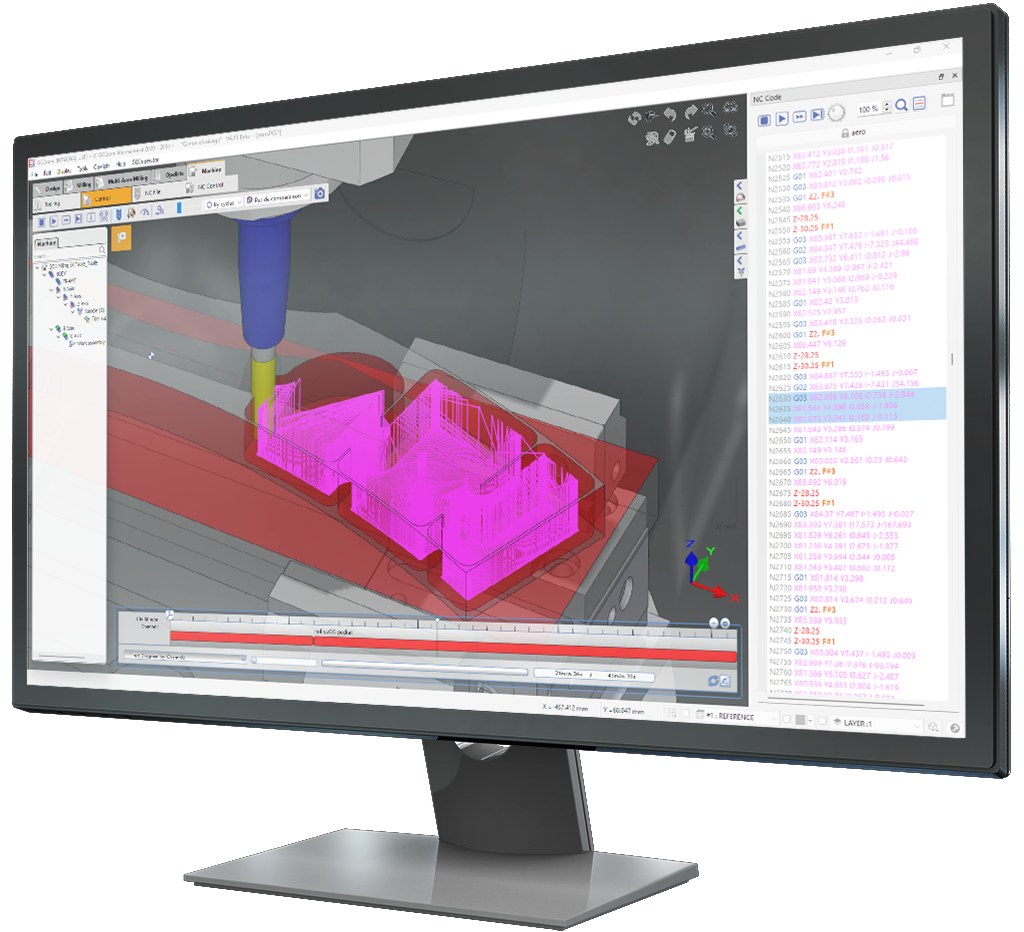

Reach the maximal potential of your machine tool thanks to millyuGO

Designed by GO2cam, millyuGO® is the answer to specific issues raised by high material removal rate productions.

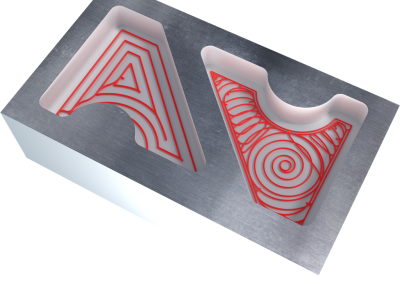

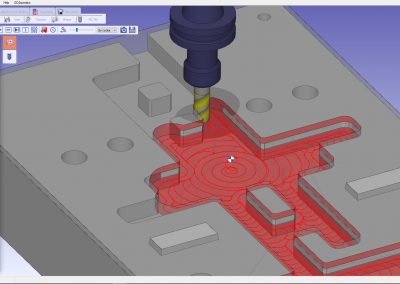

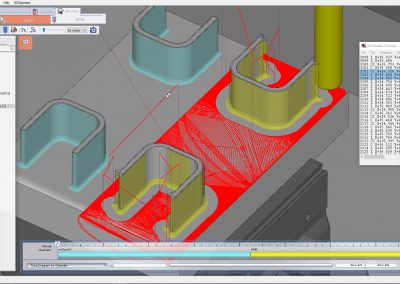

millyuGO® is an owned and patented technology : It calculates all the toolpath in order to optimize forces exerted on tool and spindle, from the first roughing cycle to the finishing.

Not less than three different patents are combined to offer our users this unique machining experience. All the potential of millyuGO® is particularly breathtaking for hard metals machining.

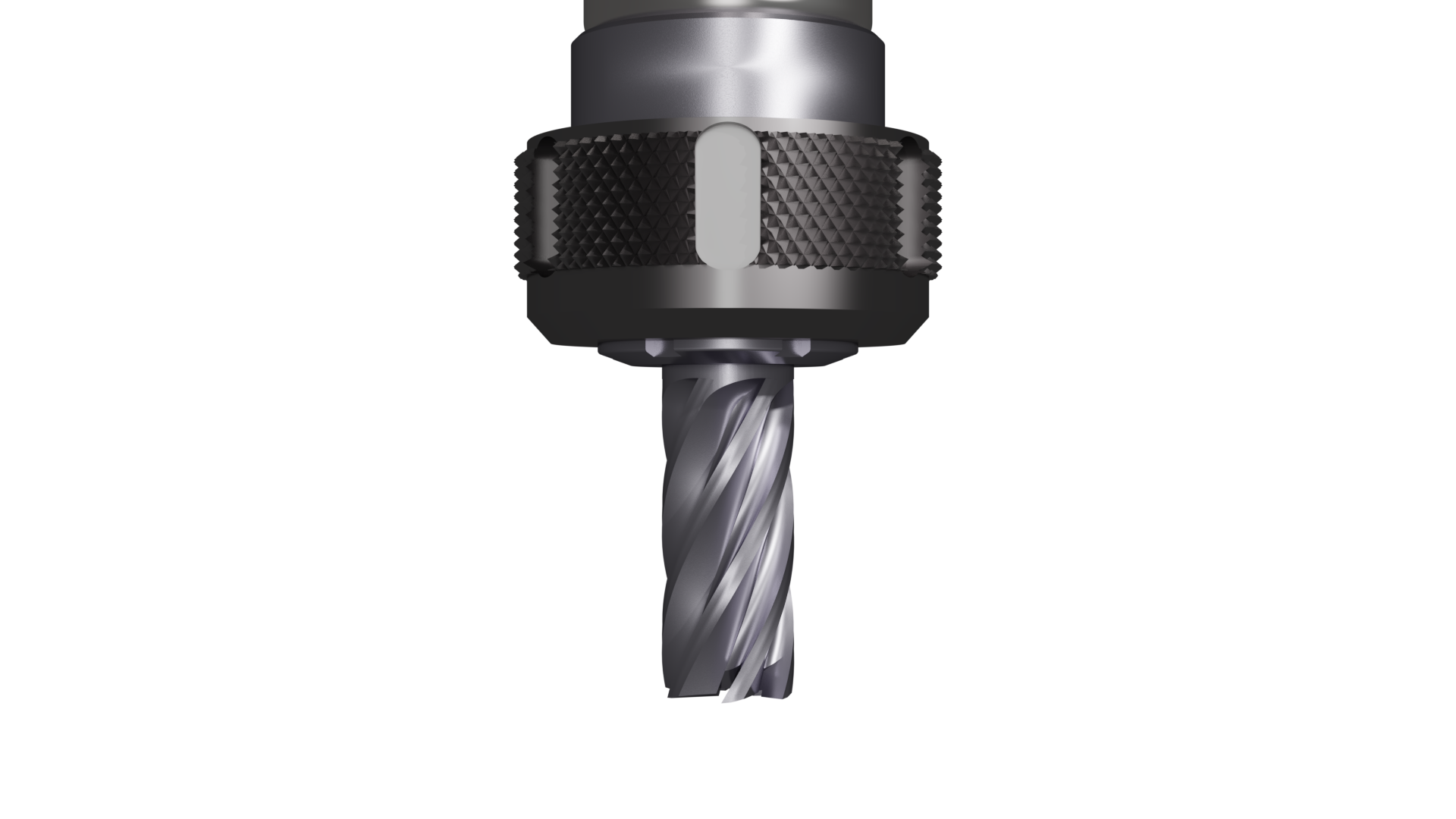

- Increased tool life : up to 6 times*,

- Shortened milling time : up to -80%*,

- Hard material milling : Titanium, Inconel, Stainless Steel,

- Thin wall avoidance toolpath : no more wall resonance vibration and breaking,

- Best finishing quality of the pocket bottom and walls,

- Reduced vibrations and resonances experienced by tools working in tough areas.

*Maximum identified values. Tool life and milling time can vary depending of machined parts, machine quality and its age.

You produce high material removal rate parts ?

Even on small series, you can save time and money.

Invest into millyuGO® for a more profitable production.