March 2025: GO2cam V6.12 – Innovation and Artificial Intelligence Serving Machining

GO2cam International is proud to announce the release of its new version, GO2cam Production V6.12, scheduled for March 3, 2025. This update marks a turning point in precision machining by integrating cutting-edge technologies, including Artificial Intelligence (AI), to enhance the user experience and optimize operational productivity.

AI at the Heart of Innovation: A Chatbot to Guide Users

Always at the forefront of new technologies, GO2cam explores and leverages the incredible possibilities offered by AI. V6.12 introduces a chatbot that will guide users at every step, directing them to the appropriate documentation and providing online assistance translated and synchronized into 10 languages, ensuring greater global accessibility.

This new version goes beyond AI integration, bringing numerous functional improvements:

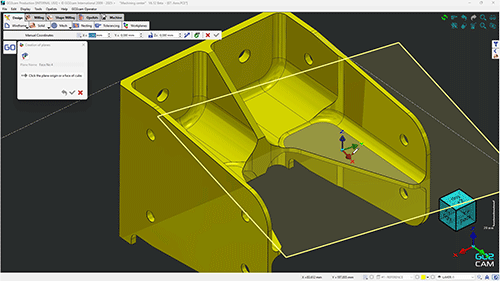

Intelligent Workplane Creation

GO2cam V6.12 introduces a unique and intuitive process for workplane creation, offering greater flexibility.

Now, a preview feature is available, and workplane editing has become more efficient, making the process even smoother and faster.

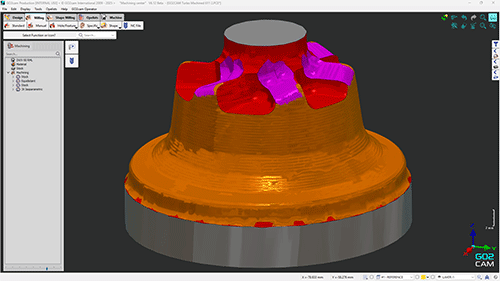

Optimized Machining Stock Management

GO2cam V6.12 features a mesh-based stock modeling approach, significantly reducing calculation times while maintaining high precision.

By simplifying part geometry through meshing, this method optimizes the calculations required to determine machining toolpaths. This time-saving approach leads to faster part preparation without compromising quality, ensuring overall efficiency throughout the manufacturing process.

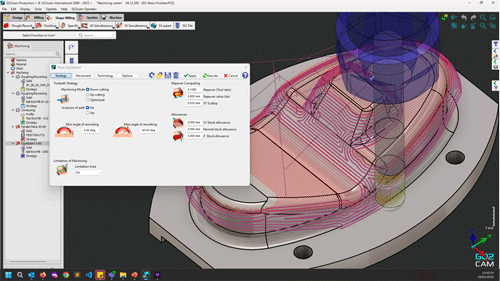

3-Axis Milling: More Powerful, More Efficient

Slope cycles have been improved to offer precise control over rework zones based on angular ranges.

This enhancement allows for more efficient back-and-forth toolpaths, while minimizing the risk of errors and optimizing milling quality.

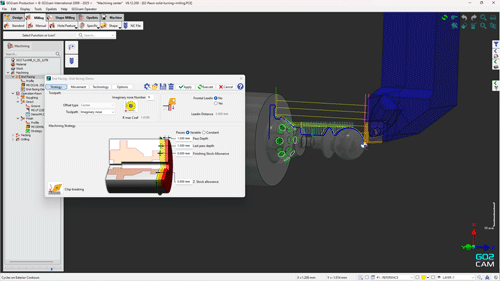

New Features and Enhancements in Turning

GO2cam V6.12 also brings significant improvements to turning, including:

- A end facing cycle applicable to all shapes, including curved profiles,

- Avoidance of perpendicular cavities in external cycles,

- A multi-groove optimization option, particularly useful for Swiss-type turning, allowing complete groove machining from roughing without repositioning the part in the guide bushing.

Increased Productivity with AI Integration

GO2cam V6.12 doesn’t just meet today’s needs—it anticipates the future by providing an enhanced user experience.

By leveraging Artificial Intelligence to improve processes and integrating tools like the multilingual chatbot, this new version allows every user to work faster, more efficiently, and with greater ease.

With GO2cam V6.12, you now have an advanced machining solution that not only simplifies complex tasks but also optimizes every aspect of your production.

Get ready to discover the next generation of machining with GO2cam V6.12 – AI and innovation driving your productivity!