March 2024: GO2cam Production unveils version 6.11

As a software dedicated to machining experts, GO2cam Production this year again integrates many new features in terms of machining techniques:

- Adding two new 4 axis simultaneous roughing operations enable to offer a rich and complete 4-5 axis module,

- in Wire EDM, solid part analysis includes a new fully automatized assignment of strategies,

- GO2cam Turning offers new pecking options to machine in Z or X axis only, Zigzag groove has a new toolpath strategy and we added the tool finder preselection in the drilling cycle,

- Milling is also highly improved by the ability to mill slot shapes with a tool of same size, the contouring cycle can generate loops in outside corners and Lens mill cutter is now available in many 3-axis operations,

- Finally, the user experience reaches a high level thanks to the new management of origins and the implementation of comparison inside the MTE simulation!

Discover so many other new features in the new GO2cam V6.11!

Here are some highlights:

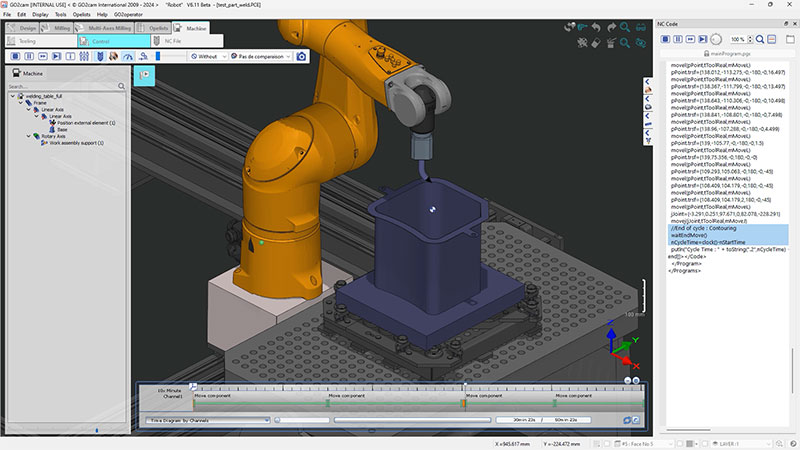

GO2cam Robots

GO2cam Robots is an integrated solution that revolutionizes offline programming for robots. By combining CAD/CAM capabilities with dedicated tools, it allows users to easily create and manage tool paths for robots, much like for machine tools.

Additionally, it provides accurate simulation of the robot’s position during its movements, acting as a digital twin. Whether you’re working on simple or complex tasks, GO2cam simplifies programming and optimizes your robot’s performance.

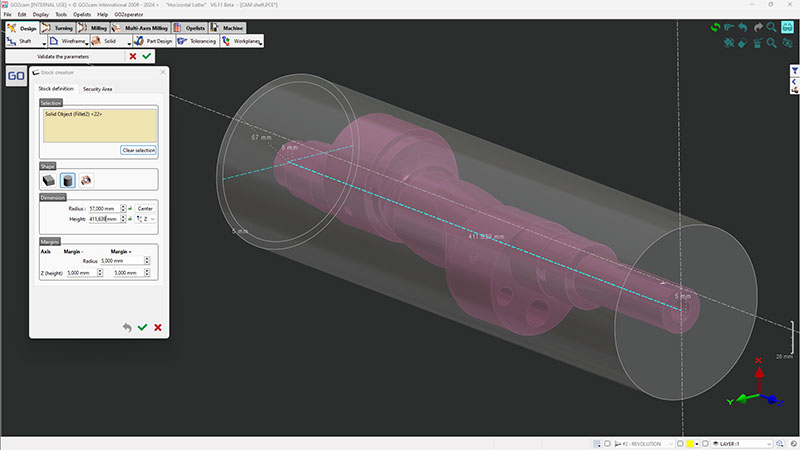

New stock creation

The Creation of Stock has been completely renewed in GO2cam V6.11. Powerful new Features are available:

- New Dialog and homogenization in the 3 situations of creation, edition & import of solid,

- Dynamic creation: dimensions are displayed and editable, orange color shows exceed of limits,

- Stock size can be defined either by block size (Length, Width, Height) or by margins along the axis. These margins can have different values: X-, X+, Y-, Y+, Z-, Z+,

- When using margins for creation, geometry can be linked with stock and safety area,

- Cyclindrical stock can now be defined upon any axis in milling,

and many other improvements have been developed to enhance your comfort in daily use!

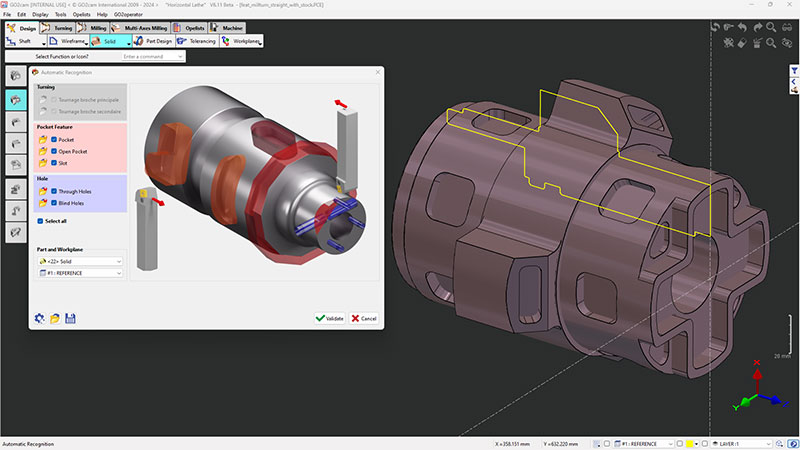

Milling features in TurnMill workpiece

Thanks to the automatic recognition of features, program your TurnMill parts in just a few minutes. The geometric and topological analysis of the solid part allows for the identification of all machinable axial and radial prismatic shapes (flats, keyway grooves, pockets, holes, etc.), as well as contoured shapes. Combined with the power and flexibility of Opelists, you can effortlessly achieve a complete range of turning and milling machining.

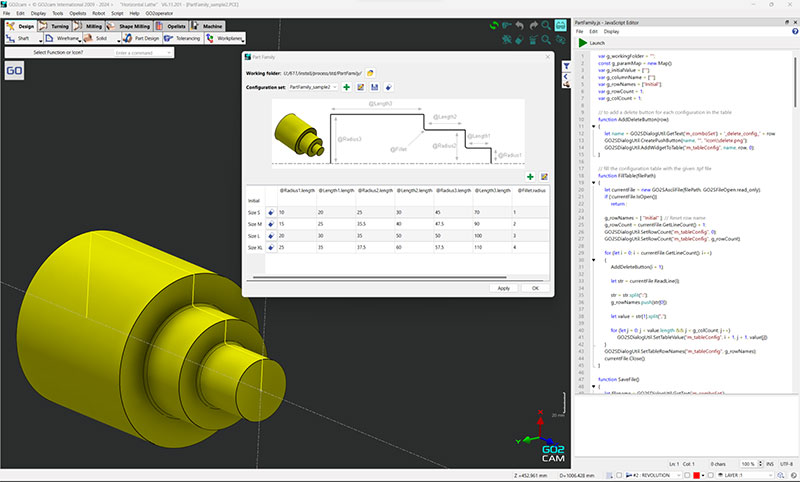

Javascript API

GO2cam’s new Javascript API is the easiest way to enhance GO2cam capabilities for specific needs and to empower automation abilities.

Combining both a popular langage and an embaddded code editor, GO2cam makes it easy to develop your own functionnality to process specific tasks or to accelerate parts of your process.

New User experience

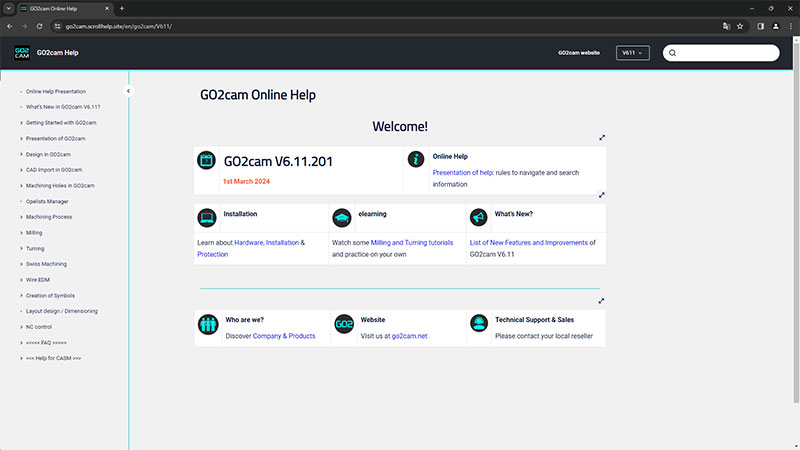

- New Help File (F1) and What’s New section: Explore the enriched Online Help and What’s New section for GO2cam software, your ultimate resource for streamlined assistance and the latest updates. Access a user-friendly interface to quickly find answers, stay informed on the newest features, and delve into a comprehensive library of over 500 explained topics.

- Web Portal: a platform designed with our users in mind. It’s a tailored ecosystem offering to GO2cam users a suite of services, products, and utilities to improve User Experience.

Contact us for more information!