GO2cam 2026: The Next Generation CAM Software for Precision Machining

From March 2nd, discover how GO2cam 2026 redefines mechanical programming with an intelligent workflow, a modernized interface, and enhanced performance in milling, turning, and EDM.

Today’s machining industry demands flawless responsiveness. To meet the challenges of Industry 4.0, GO2cam 2026 introduces a completely rethought approach to CAM programming. This new version accelerates the preparation of your CNC programs while ensuring unparalleled precision and user comfort.

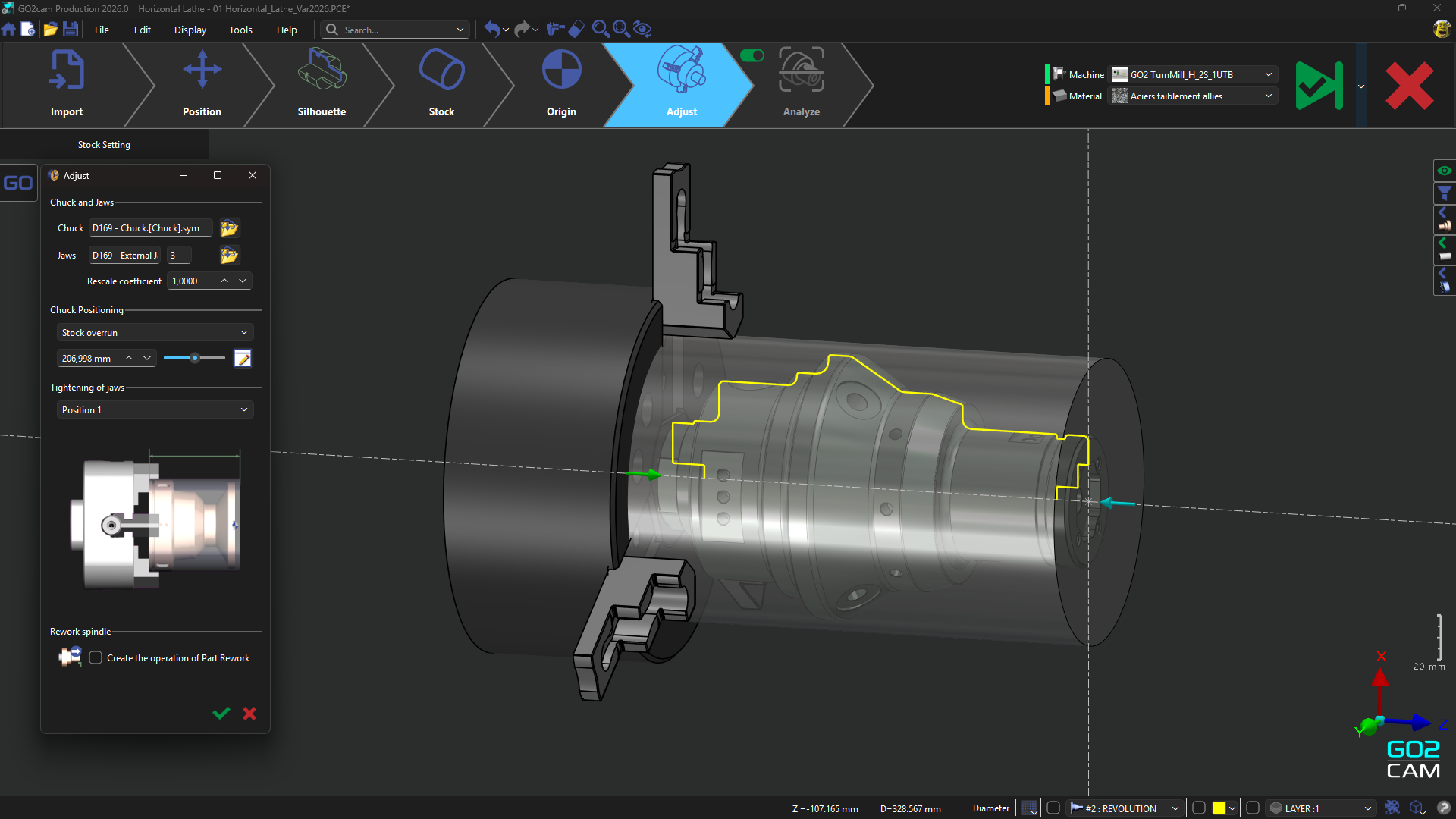

An Intelligent Workflow for Advanced Automation

From the moment you import your CAD files, GO2cam 2026 becomes a true co-pilot. The software guides the user through each key step to secure and accelerate production startup:

- Simplified Configuration: Selection of machine tool and material.

- Stock Preparation: Intuitive definition of origin and part positioning.

- Fixture Management: Automated integration of fixtures and clamping devices to avoid any collision.

- Automatic Feature Recognition (AFR): Intelligent detection of geometric shapes for assisted programming.

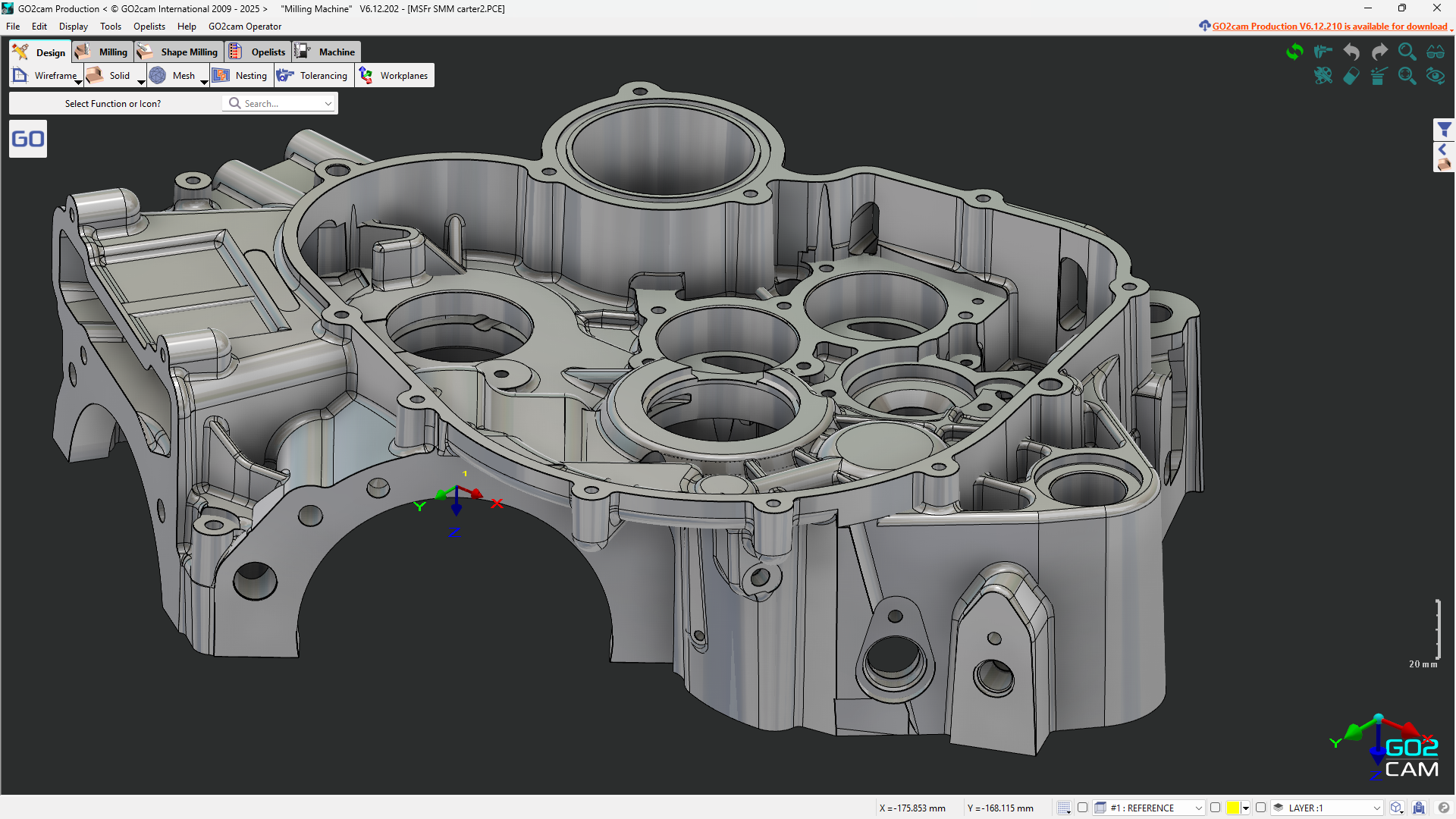

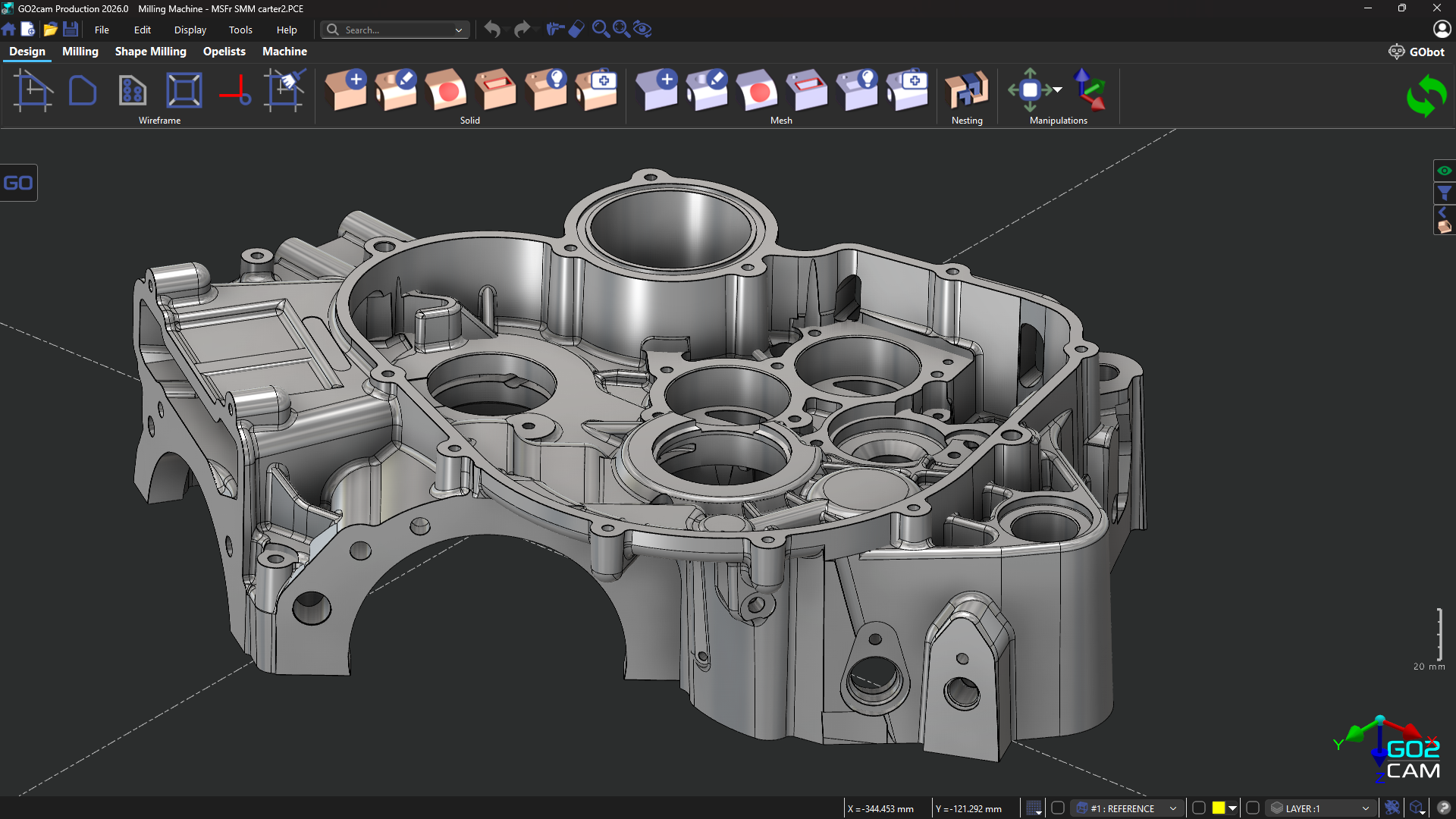

A Modern and Productive User Interface

The ergonomics have been completely redesigned to reduce the number of clicks and limit programmers’ cognitive fatigue:

- Contextual Ribbons: Direct access to the commands you need.

- Dark Mode: Optimal visual comfort for long work sessions.

- Automatic Simulation: Instantly visualize your toolpaths after each modification.

- Dynamic Machining Tree: Fast updates and increased readability of operations.

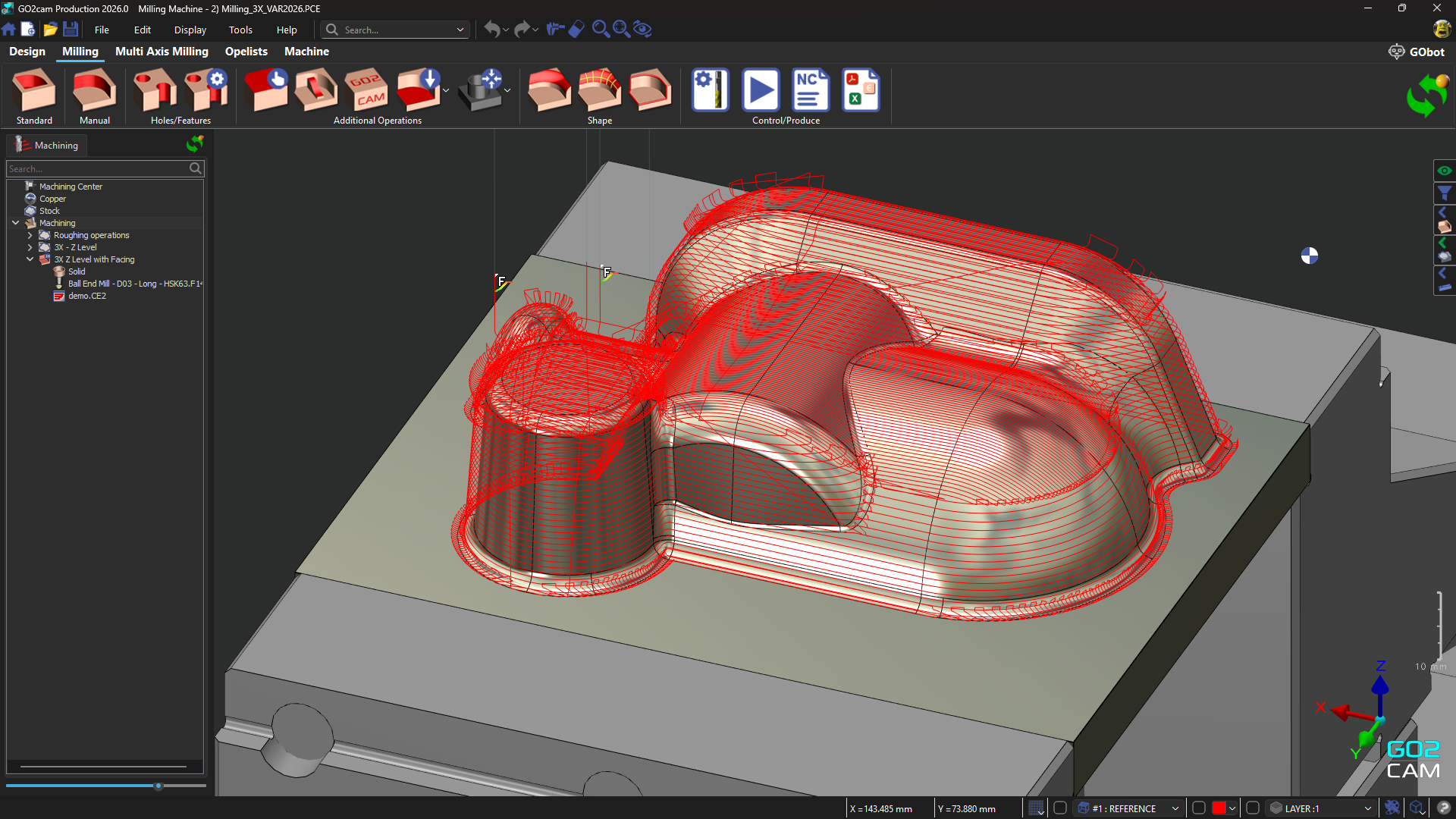

2.5-Axis, 3-Axis and Multi-Axis Milling

GO2cam 2026 optimizes your cycle times with new multi-core calculation cycles:

- Hybrid 3-Axis Strategies: Combination of Z-level and facing for flawless finishes.

- APF/APL Pass Management in 3-Axis and Pocket: Customization of first and last pass depths.

- Nombreuses innovations métier dans les opérations de Forage, d’Interpolation et d’alésage entre autres.

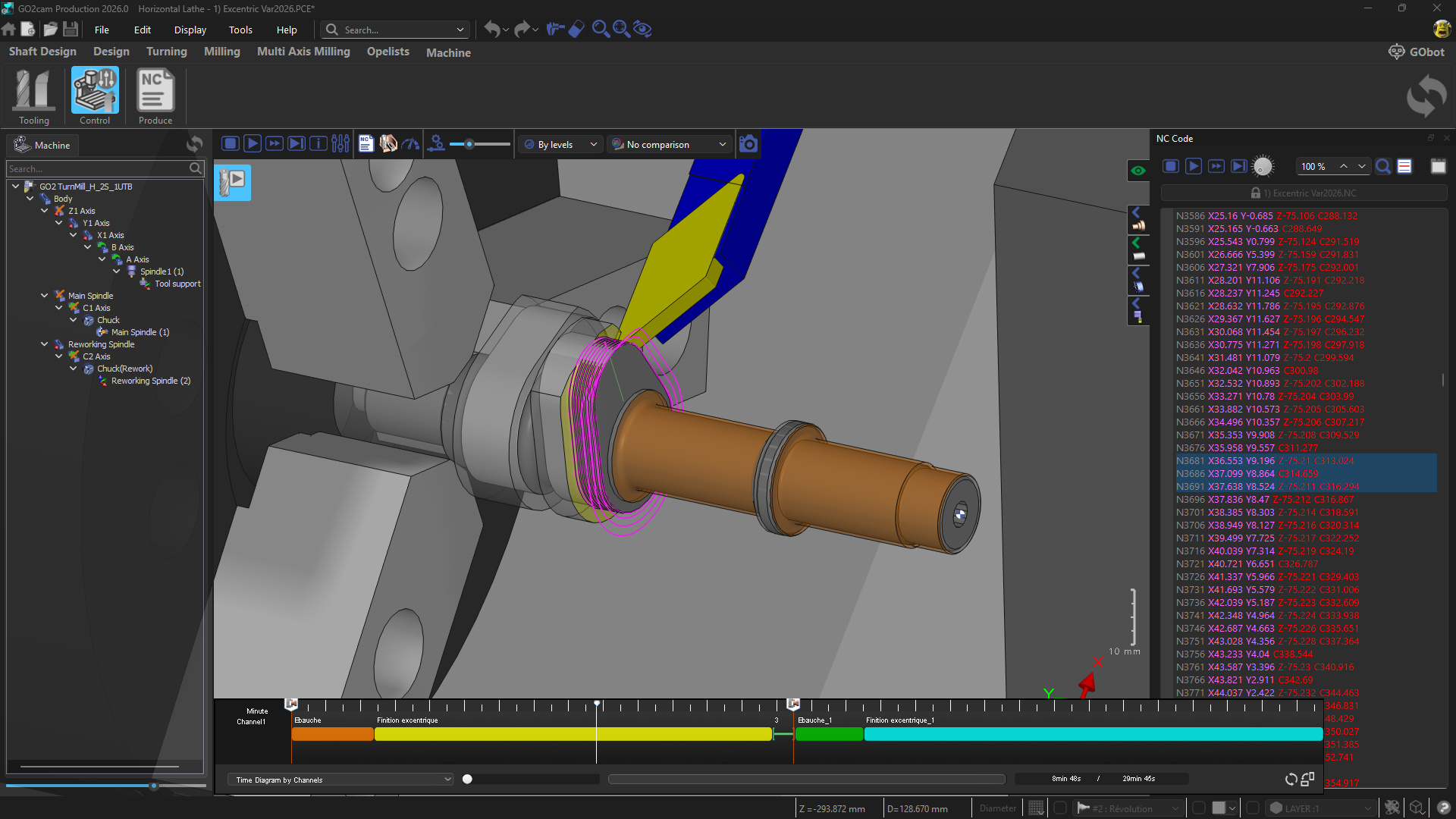

Turning and Swiss-Type Lathe

The turning module gains versatility for complex parts:

- Swiss Slice: Swiss-type technology integrated into standard turning to machine the part in sections along the Z-axis.

- Eccentric Machining: Simplified programming of parts with eccentric shapes such as cams.

- Safe Plunging Operation: Zigzag strategies with intelligent retraction.

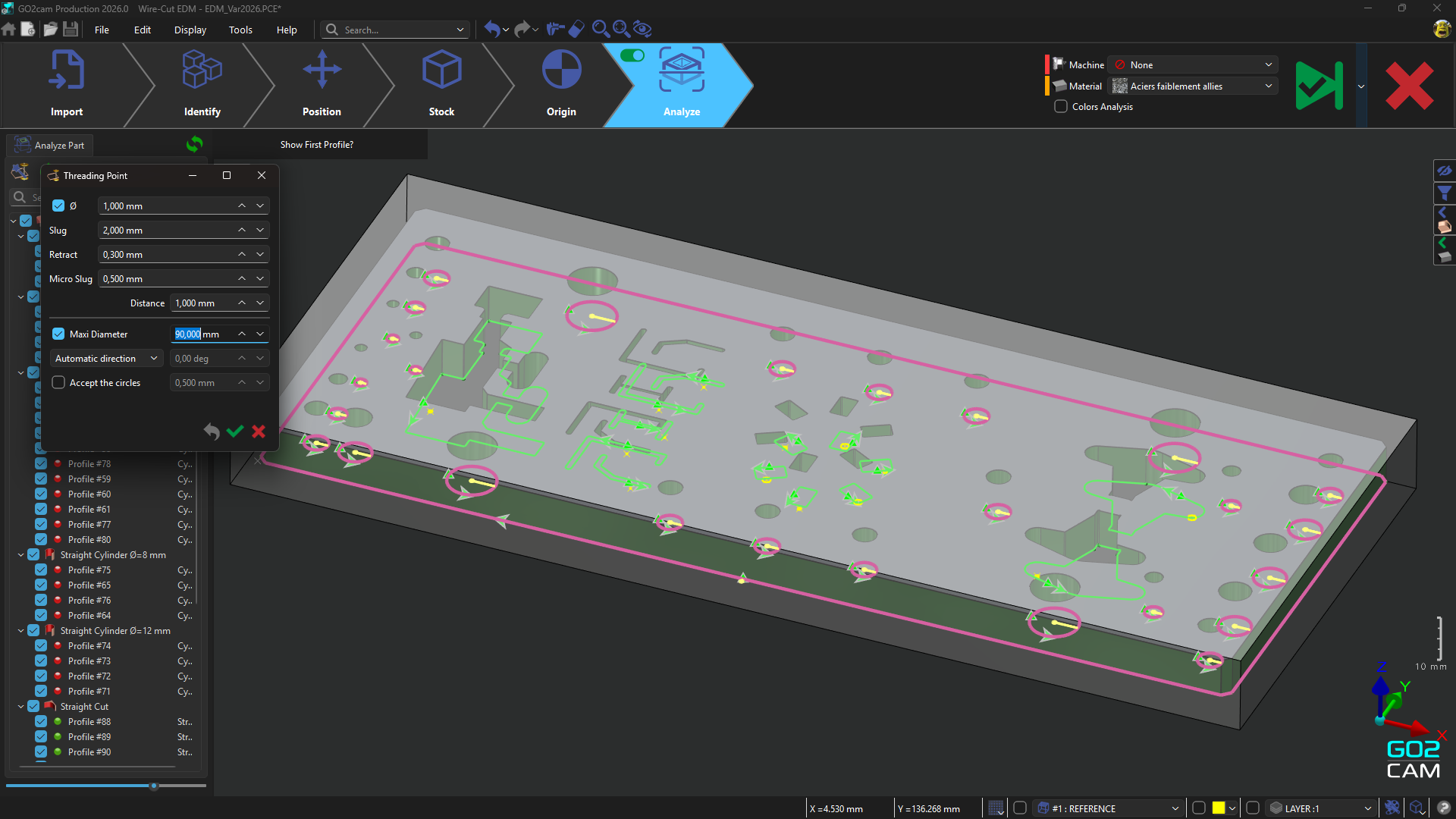

Wire EDM

Automation reaches a new peak thanks to color analysis. The software automatically detects threading points and applies the best strategies according to face typology, ensuring reliable and ultra-fast programming.

Summary of GO2cam 2026 Benefits

✓ Immediate productivity gain thanks to guided workflow

✓ Increased precision of tool paths

✓ Drastic reduction in programming errors