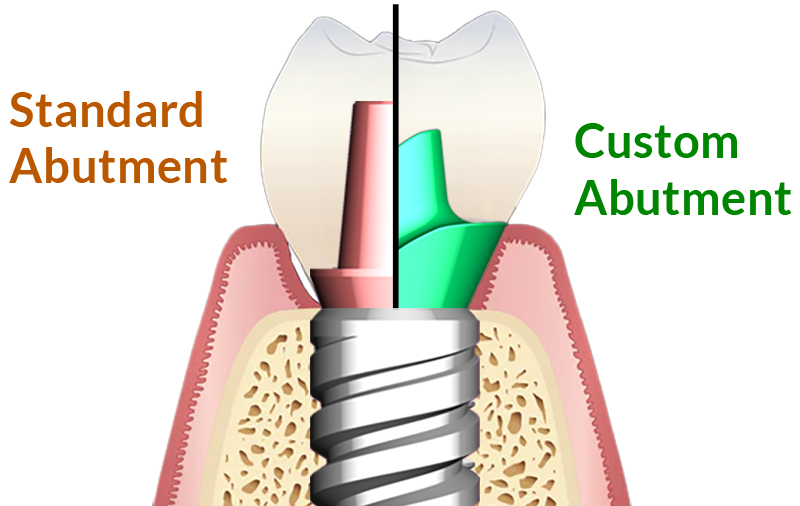

Custom Dental Abutments

What is CASM

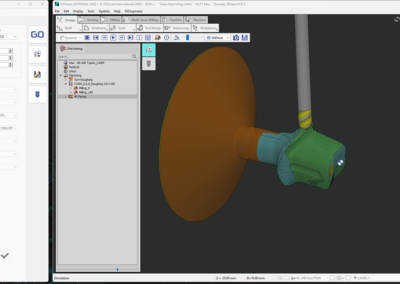

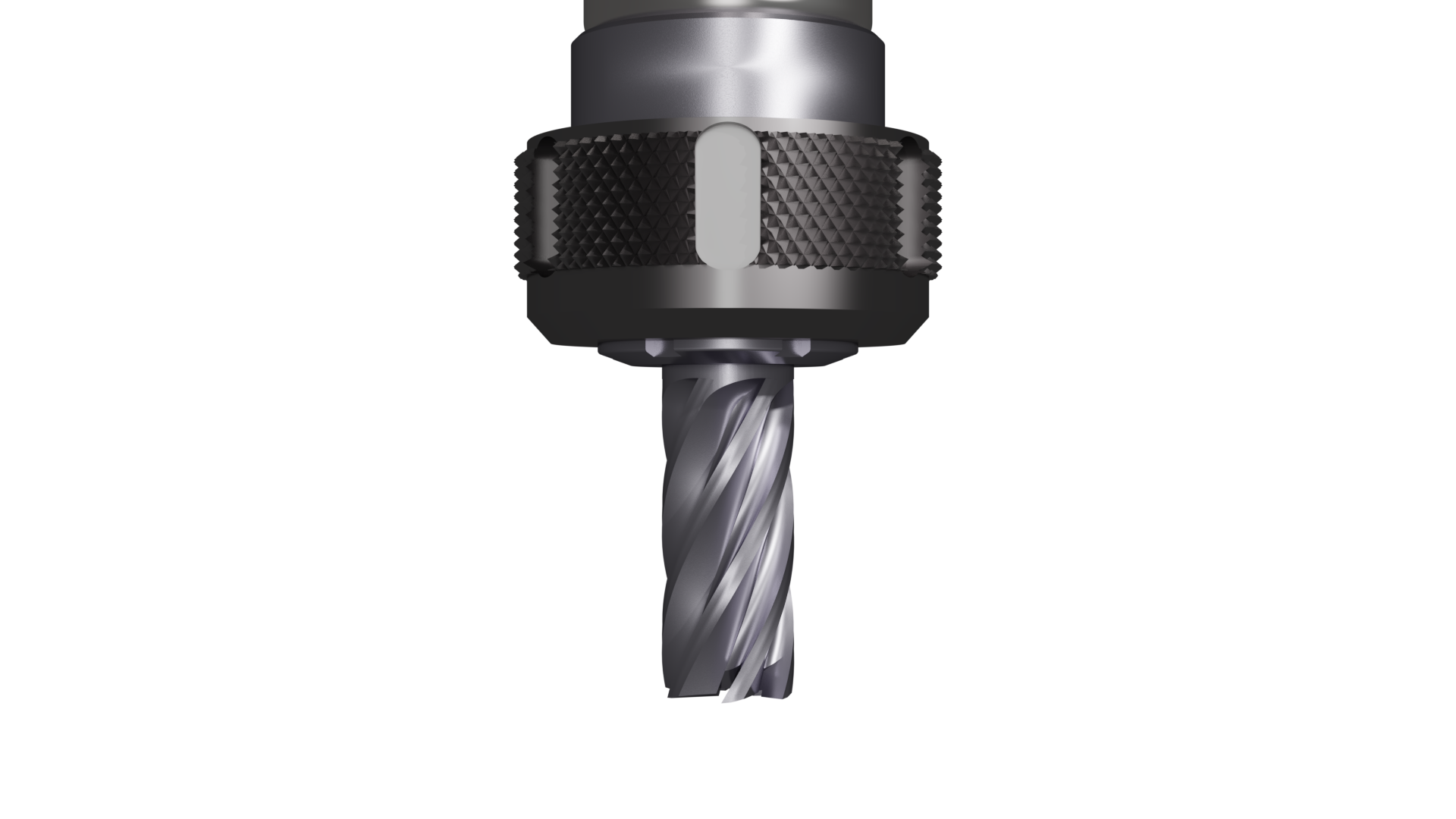

CASM, acronym for Custom Abutment Swiss Machining is an exclusive product from GO2cam, specially designed to revolutionize the machining of dental abutments. Typically, abutments are machined on milling machines from pre-milled material blocks for the implant area. With CASM, abutments are machined on Swiss lathe machines. This innovative technology provides a precise and efficient approach to the custom manufacturing of dental abutments, meeting the specific needs of dental professionals.

Advantages of Custom Abutments

- Optimal Comfort: Thanks to a perfect fit, the custom abutment offers an optimal level of comfort, minimizing any discomfort or irritation for the patient.

- Maximum Hygiene and Oral Health: Custom manufacturing ensures maximum hygiene, meeting strict oral health standards, which is essential to prevent infections and promote long-term oral health.

- Improved Durability and Reduced Risks: Customized abutments, tailored to the specific needs of the patient, offer increased durability and reduce the risks of complications, ensuring long-term stability and minimizing functional problems.

Milling (premilled) vs. CASM (Swiss Machining)

Thanks to CASM, Swiss type lathes, initially used in the dental industry for mass production of standard abutments, screws and implants, have expanded their application to the production of individual parts. This evolution opens new perspectives, providing increased flexibility in the production of personalized abutments.

Compared to the traditional milling method from a pre-machined block (premilled), Swiss machining offers significant advantages:

- The Swiss machining technique enables the entire abutment to be machined in a single operation, ensuring optimal precision.

- By eliminating the need to manage a specific “premilled” block for each connection, this approach reduces logistical constraints.

- Machining time is at least halved compared to a milling machine, making the cost of producing a personalized abutment on a lathe highly competitive.

Despite these advantages, using a lathe requires specific skills in handling the machine and adapting the workspace. Concerns related to using a lathe are nevertheless mitigated through CASM, whose interface we have significantly improved. This enhancement notably simplifies and accelerates the programming process, making it more accessible for dental technicians to use a lathe.

Precision in milling is crucial, given the potential costs associated with errors. In traditional milling, an error in the choice of implant connector leads to the irreversible loss of the premilled block. Similarly, a worn roughing tool can compromise the integrity of all the abutments being manufactured.

On the other hand, in Swiss machining, the costs associated with an error are limited to the lower price of the titanium bar, providing financial security in case of malfunctions in the manufacturing process.

Comparative Table 'Premilled' vs CASM

| Milling (premilled) | CASM (Swiss Machining) | |

|---|---|---|

| Machining TimeThe use of CASM reduces machining time by at least 2 compared to milling. | > 30 min | 15 min |

| Abutment Quality | | |

| ConnectorThe absence of a connector with CASM allows for faster and more precise machining. | | |

| Machine FootprintDue to the presence of the bar feeder, the lathe has a larger footprint than that of a milling machine. | | |

| Machine Cost | | |

| Part Cost | | |

| Ease of Settings | | |

| Stock ManagementIn milling, the management of multiple 'premilled' blocks is necessary, while in CASM, machining is carried out from a single bar. | | |

| Stock Supports ManagementIn milling, the management of multiple block supports is necessary, whereas in CASM, there is no need. | | |

| Tool Life | | |

| Adjusting Support OriginsIn milling, each origin of each support must be adjusted, whereas this is not necessary in CASM. | | |

| RepeatabilityCASM provides consistent accuracy in producing identical parts. This quality is essential and guarantees reliable and defect-free manufacturing, regardless of production volume. | | |

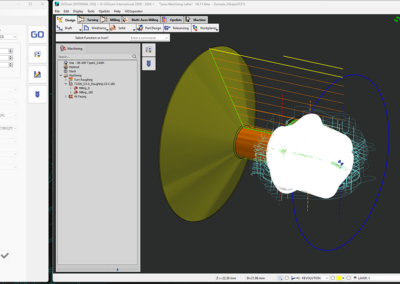

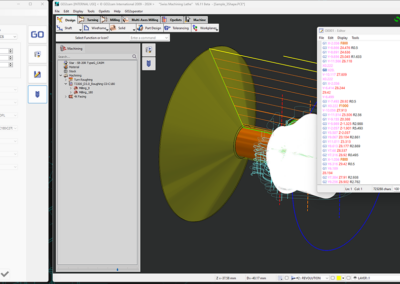

Main Stages of CASM

- Loading the STL File: The process begins with the loading of the STL file, defining the geometry of the dental abutment. This step is the essential starting point for custom machining, where every detail counts.

- Automatic Positioning of the Abutment: CASM integrates a function that positions the abutment along the Z-axis of the machine. This preliminary step ensures a solid foundation for the overall process.

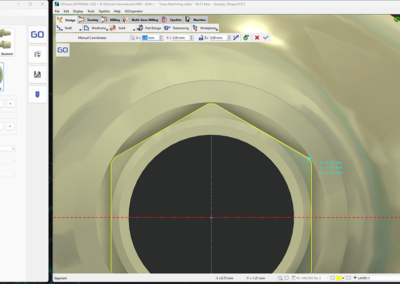

- Abutment Indexing: Precise alignment of the piece is crucial for optimal results. CASM allows perfect alignment based on specific reference points, ensuring consistency in the final results.

- Connector Selection: Definition of the connector from a library for precise machining. This step ensures perfect quality for the interface with the implant.

- Definition of the Safety Zone: CASM allows the definition of a protective zone, providing peace of mind during the machining process.

- Configuration of the Reworking Zone (if necessary): Some operations require specific adjustments. CASM offers the possibility to configure a reworking zone, adapting the process according to individual needs for optimal customization.

- Definition of the Axial Milling Zone: Machining the face of the dental abutment is a crucial step for aesthetics and functionality. CASM allows the precise definition of the milling zone, guaranteeing results that meet the expectations of dental professionals.

- Calculation: Once all configurations are completed, CASM performs the necessary calculations to optimize machining (creation of geometries, application of machining cycles). This step takes into account all variables defined earlier and ensures maximum efficiency in the process.

- CN File Creation: Finally, CASM results in the creation of the CN file, ready to be used on the lathe machine. This file contains all the necessary information to guarantee precise and efficient machining of the personalized dental abutment.

Conclusion

The CASM by GO2cam represents a significant advancement in the field of Swiss machining for custom dental abutments. Thanks to CASM, dental professionals can benefit from a fast, comprehensive, and efficient solution to meet the specific demands of their patients, while ensuring unparalleled quality and precision in the custom dental abutment manufacturing process.

With CASM, GO2cam continues to push the boundaries of precision machining for the dental industry, providing an innovative and reliable solution.